Loading Details Of Stone Product

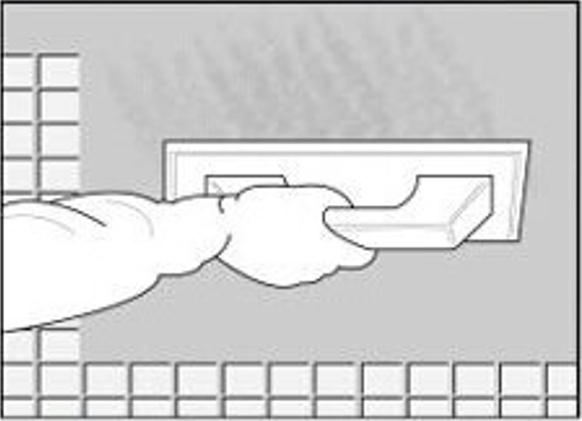

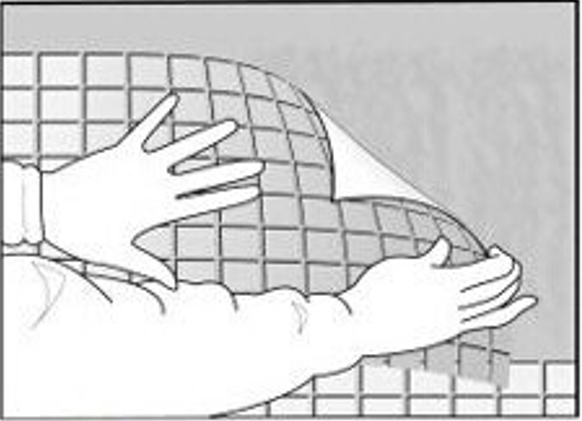

The stone product are extremely fragile during the handling and unloading process. If it is accidentally damaged, the loss will be serious. So let us share something during the stone handling process and how to avoid unnecessary dangers.

Precautionary and prepared.

In order to be safe and free from loss, it can be prepared according to different conditions, product size, quality, distance, and different modes of transportation.

▶ If the large-size big slab, we suggest to use the hard wood for firmness.

▶ If the small slab, can be bundled with wooden slats and shovel.

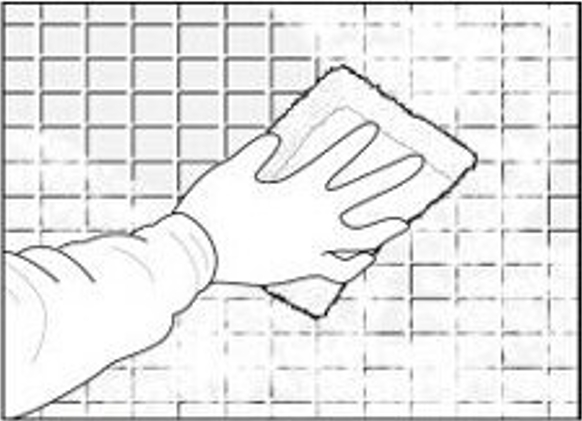

▶ Specialty products and handicrafts should be packed in cartons and wooden boxes to protect sharp corners.

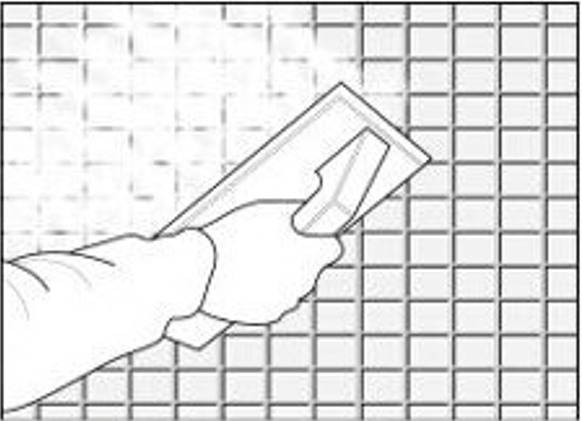

▶ It is strictly forbidden to pack the white and easily contaminated products with colored plastic and straw rope.

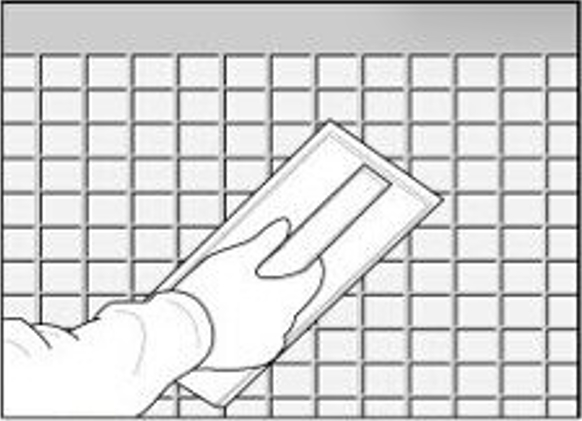

▶ The package should be secure and easy to load and unload.

▶ You need to write the box number and attached the packing list on the package.

▶ Pack with plastic film to prevent rain.

▶ The surface of the working piece should be foamed, and the bottom of the package should be filled with two crossbars for loading and unloading.