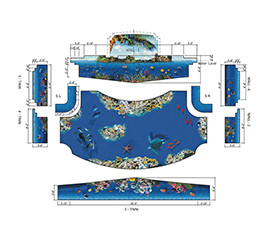

PROFESSIONAL DESIGN

The brilliantly talented, design savvy team of PFM specializes in helping you customize unique mosaic design that will make your construction more distinctive. We will collaborate with you to transform any idea and requirement you want into a custom mosaic feature.

EXTENSIVE TILE SELECTION

Our experienced staff will help you navigate our diverse material selection to find the right one for the budget, performance, demands, and overall aesthetic of your project. We provide free, project specific samples. So you can coordinate finishes and impress clients.

HIGH-EFFECTIVE PRODUCTION

Our modern factory system and advanced automatic production equipment as well as skilled worker can assemble custom mosaics more precise. Strong production capacity ensures the mosaic production will be delivered on time.

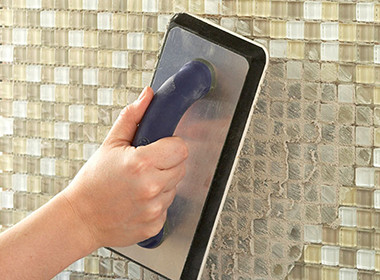

INSTALLATION FRIENDLY

PFM mosaic products are easy to be installed. We have a professional and skilled installation team who can provide guidance for your projects. PFM's super talented team is competent in various styles of mosaic products.